Automated Stock Count

Do you know what you have in stock right now? What of every product code? In every location? If only, eh? We all need to do manual stock takes at...

Complete accounting solutions focussed on profit and growth

Inventory management systems play a crucial role in thriving product businesses

Automating your core systems is the key to efficiency and effectiveness

Scalable software that grows with you

Product and inventory software that makes sense

Seamless integrations and automations

Whether they use a single solution or a full end-to-end integration of multiple software packages we are proud to be a part of our client's success.

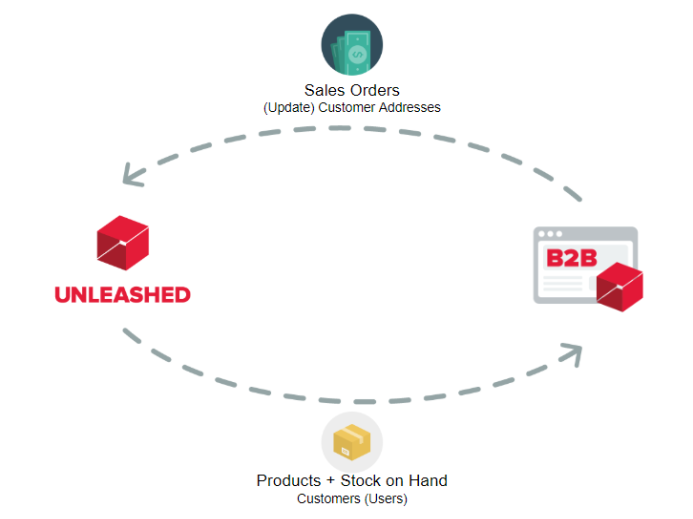

Unleashed Software is a powerful cloud-based inventory management tool that allows businesses to accurately manage their inventory in real-time. Unleashed allows you to easily and accurately track stock in real-time across various locations for visibility on all inventory management processes and transactions. With such dynamic inventory information, businesses can make better data-driven business decisions.

In business, getting access to the inventory you need quickly is key. Although investing in forecasting is sensible, accurately forecasting the inventory that you will need in a quarter or even a month is incredibly difficult.

For small businesses, it might only take one unusually large order to throw off the period’s forecast. Even larger businesses can be caught out by unexpectedly large fads, trends and seasonal fluctuations. Although holding large reserves of inventory is one way to ensure your business has everything it needs on hand, a better solution may be to focus on reducing lead times in your supply chain. Here’s how your business can reduce its inventory lead times.

Working with multiple suppliers can be highly time-consuming and can also create frustrating inventory gaps where you have all the inventory except for one crucial component from a small supplier. This is a common frustration in manufacturing inventory management.

If you work with a small set of suppliers, different products will ship together, helping to cut down on logistics and potentially reduce lead times. Working with a smaller group of suppliers also makes it easier to communicate and foster better relationships with each one.

Once you have selected reliable suppliers, set clear timeliness expectations and settle on a metric to assess performance. Ideally, performance expectations should be formally set out in an agreement that you can point to if issues arise. If performance slips and the supplier does not successfully remedy the issue, consider switching suppliers.

Generally, local suppliers lead times are shorter than overseas suppliers. This is because they don’t need to ship the products by sea or air, instead shipping on land and removing the need for customs and excise process. Some businesses prefer to work with suppliers from the same locale as it’s easier to communicate.

Many businesses focus on supplier performance without considering ways their business practices may affect lead times. Ideally, customer orders would trigger supplier orders in near to real time. While this may not be practical for your business, a key way to reduce lead times is to place orders as soon as practicable once you have received a customer order.

It is likely that your suppliers also wish to reduce their lead times. By providing them with as much information as possible about expected demand, your suppliers may be better placed to prioritise their own workloads, resulting in shorter lead times and a stronger supplier relationship.

Do you know what you have in stock right now? What of every product code? In every location? If only, eh? We all need to do manual stock takes at...

2 min read

Business Intelligence (BI) is part of Unleashed’s inventory management offering that brings together the best tools to analyse your...

The Unleashed B2B portal provides a self-service platform for your business-to-business customers to place orders, allowing customers to manage their...