Ecommerce - Mastering Stock Turn for Success

For any physical product based business selling online (B2B or D2C), efficient stock management is vital to maintain a competitive edge in the...

Complete accounting solutions focussed on profit and growth

Inventory management systems play a crucial role in thriving product businesses

Automating your core systems is the key to efficiency and effectiveness

Scalable software that grows with you

Product and inventory software that makes sense

Seamless integrations and automations

Whether they use a single solution or a full end-to-end integration of multiple software packages we are proud to be a part of our client's success.

1 min read

Philip Oakley

:

Jul 17, 2023 1:17:00 PM

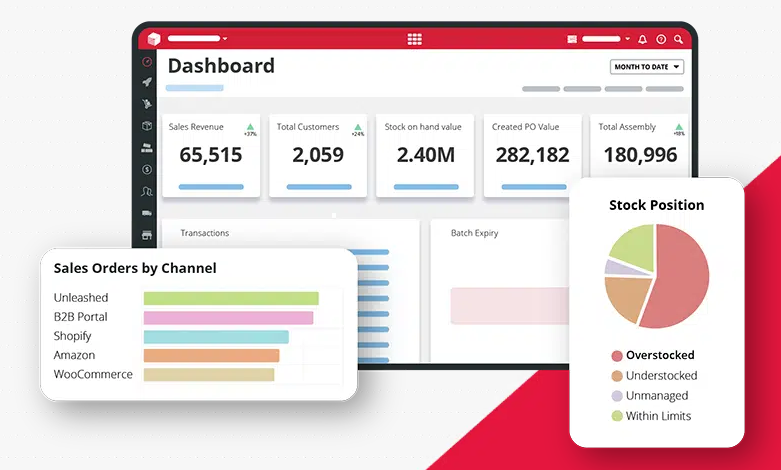

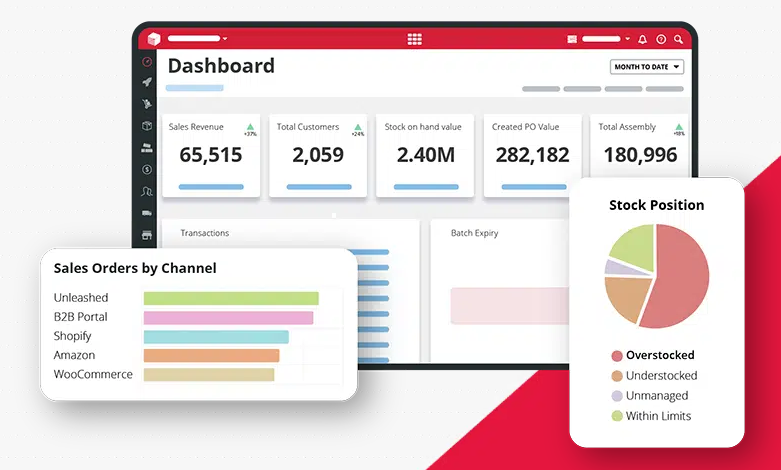

This inventory management system Unleashed manages bills of materials, assemblies, wastage and cost tracking - all in real time - whilst also allowing batch, best before or serial tracking of goods at all levels of your production.

Primarily an inventory management system, designed to help you keep track of your stock and the cost of your stock, unleashed is a fantastic cloud-based solution for manufacturing businesses.

A huge part of tracking stock for many businesses is managing goods during assembly and Unleashed’s production module is built with this in mind. It manages bills of materials, assemblies, wastage and cost tracking - all in real time - whilst also allowing batch, best before or serial tracking of goods at all levels of your production.

Bill of Materials is a module in Unleashed that acts as saved records of the component products of your assembled goods. Unleashed allows you to create a bill of materials for each product that requires assembly. Each bill of materials contains all of the component products, their quantity and any associated wastage. If there is a fixed labour or overhead cost associated with the assembly, this can also be tracked.

This allows assembled goods to reflect a true cost compiled from the cost of the whole process.

The production module then uses the saved bill of materials in the assembly process. This acts as a blueprint but can still be edited on a case-by-case basis. So, if the cost of labour is slightly higher or there’s more wastage on a production run, the cost of the assembly is accurately captured. The specific batch or serial numbers of component or assembled products can also be recorded in each assembly, giving full traceability throughout production.

The auto assembly feature can also be used to save time during the assembly process, allowing assemblies to be created from sales orders and completed if components are in stock. The Unleashed Production module is used by businesses across a wide range of industries, from distilleries and pharmaceutical companies, to florists and cosmetic providers. Unleashed production solutions keep businesses producing, tracking costs and delivering great products to their customers. If you’re interested in how Unleashed can help your business, Outserve would love to hear from you via email, phone or book a discovery call on our website.

For any physical product based business selling online (B2B or D2C), efficient stock management is vital to maintain a competitive edge in the...

Stockouts and overstocking are both inventory management issues that can have negative consequences for a business.

Do you dream of a world where stock forecasts are simple, straightforward, and actually accurate?